Introduction

Latex nanoparticles are among the most common particles used as reference materials. Polymer lattices can be produced via various methods with emphasis on those yielding narrowly distributed, monodisperse particles. Most convenient is the production by emulsion polymerization with or without emulsifiers, with the latter giving a higher degree of monodispersity. Dispersion polymerization represents another route generally leading to broader size distributions, whereas precipitation out of solution affords particles in the microscale range. Polystyrene (PS) lattices are frequently used nanoparticles among many different organic and inorganic reference materials. The benefit of using PS is, besides spherical shape, chemical resistance and the possibility to adjust particle size, based on facile production via radical polymerization.

Besides the selected polymerization approach, further factors such as ionic strength, polymerization parameters, concentration, temperature, curing, solvents, phase interactions and the chemical composition eventually define the respective particle characteristics. Therefore, continuous monitoring of the production process is mandatory as meeting quality standards or compliance with regulations and specifications are of utmost importance both for manufacturers and customers.

Centrifugal Field-Flow Fractionation (CF3) coupled to suitable detectors, like Multi-Angle Light Scattering (MALS) and Dynamic Light Scattering (DLS), in combination with concentration detectors (UV, RI), is a straightforward setup to continuously monitor particle and polymer production on a robust and highly reproducible level. [1]

Experimental

Four PS latex samples of different nanoparticle content regarding size and/or composition were analyzed. The mixtures included samples of similar particle size but different structure (density via branching) and similar compositions along differing sizes. CF3 coupled to UV (254 nm) as well as MALS and DLS detectors were applied to determine concentration and particle size of the respective samples. The samples were prepared in a 0.2 % NovaChem solution (v/v) similar to the carrier liquid used for FFF and stored at room temperature. Overall, four samples were analyzed. The method will be addressed briefly: An exponential field decay proved to be ideal for any kind of nanoparticles to be separated on CF3. A standard method without further method development was chosen to show the ease of separation on this system (advantage of separation by density and hydrodynamic size). The initial FOCUS step provides enough time for the different sample species to relax (2 min), whereas the ELUTION step defines the starting point of sample elution. After 10 min of constant centrifugal force (2690 gravitational force equivalent / 4900 rpm), an exponential field decay over 60 min was applied.

Results

With a known sample concentration the UV signal at 254 nm wavelength was used to track the particles and compare the results to the response of the light scattering device. Similar results were obtained for all samples by comparison of LS and the UV-signals (Fig. 1). Whereas the MALS shows a higher response for the largest particles in the sample (47 min), the UV is capable of detecting small sample impurities in the FFF-system dependent peak (0.1 min, eluting first). The advantage of using both detectors is to distinguish particles/polymers from molecular sample impurities (like aromatics, residues from synthesis, catalysts or low molecular weight polymers, e.g. PEG). Separation by hydrodynamic size and density is shown to be a powerful technique offering the user the possibility to separate even two latex particles of equal size but with different density!

Figure 1 shows the overlay of the LS, resp. UV trace of each sample. Since the same fractionation method was used, the retention time (peak maxima) can be used to identify comparable samples (referred also to relative calibration). The LS and UV response of the particles decrease in the order:

Peak 1 (24 min, 34 min): Sample 1 > 2 > 3 > 4 and for Peak 2 (47 min): Sample 3 > 4 > 2 > 1.

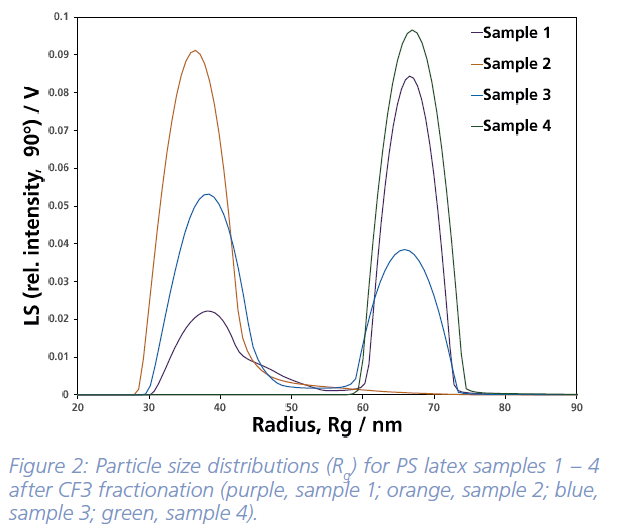

The measured data obtained from MALS showed angular dependency meeting the requirements for a spherically shaped particle (generally observed and TEM validated for latex particles).[2] The samples showed overall three different particle species. Two similar in size (39 nm radius, Rg) but of different density, and a larger particle size (70 nm radius, Rg). The fact that the size classes were resolved accurately for each sample mixture shows the benefit of combining separation and analysis of FFF and online detector systems for routine and QC applications. For detailed information about the measured particle sizes please refer to Table 1.

DLS was used to compare the measured radii of gyration with the hydrodynamic radius in solution obtained from DLS. The DLS fractograms are in accordance to MALS and UV and are omitted for clarity. The measured hydrodynamic size information is given in Table 1.

Note: The Rg-values refer to number distribution obtained from laser diffraction.

Finally, the size distribution analysis showed two particle size populations present within the four samples: 32 nm – 46 nm and 64 nm – 73 nm (Figure 2). By using the CF2000 technology three particle species were detected and separated thus highlighting the effective fractionation power of the system featuring separation by hydrodynamic size and density. In particular, the particle size distributions show increasing content of particles in the order:

Size 1 (32 – 46 nm): Sample 4 > 1 > 3 > 2 and Size 2 (64 – 73 nm)): Sample 2 > 3 > 1 > 4.

Conclusion

The CF2000 technology coupled to Light Scattering (MALS/DLS) and optionally to UV proved to be an ideal tool for identification of particle size populations in the nanoscale (mixture of PS lattices). Separation by hydrodynamic size and density (realized with CF3) is shown to be a powerful technique offering the user the possibility to separate even two latex particles of equal size but with different density (branching). The fact that the size classes were resolved accurately for each sample mixture shows the benefit of combining separation and analysis of FFF and online detector systems for routine and QC applications. Overall, the method is ideal for monitoring production processes and is thus highly recommended to any user dealing with quality control of nanoparticles.

References

[1] J. C. Giddings, Science, 1993, 260, 1456-1465.

[2] A. Walther, M. Hoffmann, A. H. E. Müller, Angewandte Chemie, 2008, 47, 711-714.