Introduction

This application note shows the separation of TiO2 nanoparticles of a model and a real sunscreen sample after extraction; two samples that are prone to fast sedimentation and thus signifi cant sample loss and size discrimination already during the injection step. Therefore, the benefit of using the “shaking option” of the AF2000-Autosampler is demonstrated.

The Experiment

A TiO2 spiked sample was prepared and characterized initially. Fractionation was accomplished using an AF2000 system equipped with a standard AF4 channel. Simultaneous particle sizing was performed using a Malvern Zetasizer Nano® S coupled in flow mode enabling the determination of the hydrodynamic size of the sample with special focus on the occurence of sample sedimentation. The TiO2 sample was prepared in ultrapure water with the addition of 0.5 vol. % detergent and 1 wt. % of TiO2 and injected into the AF4 system. A 0.05 % NovaChem (aq.) solution with the addition of 0.05 % NaCl was chosen as carrier. A standard method using a linear cross flow decay and a constant detector flow rate of 0.5 mL/min was sufficient to ensure nanoparticle separation.

Titanium Dioxide spiked Water Sample (Model Subtrate)

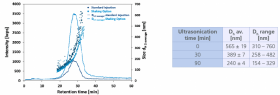

Figure 1: AF4-DLS-fractograms of the TiO2 spiked sample (dark blue: injection with “shaking option”, medium blue: injection without “shaking option”; dark blue and medium blue dots: hydrodynamic diameter, Dh).

Shaking Option: The analysis of the TiO2 spiked water sample showed a significant amount of sedimenting sample material not being injectable with a standard autosampler (Figure 1, dark blue line and dots). In contrast, by using the “shaking option” suffi cient mixing of the sample prior to injection could be achieved leading to a three times higher intensity signal along with a lower variance of the detected particle radii (Figure 1, medium blue line and dots). The sample shows the presence of TiO2 nanoparticles in the range of Dh = 85 – 490 nm. Ultrasonication promoted particle isolation thus leading to smaller detected particle sizes. The influence of the ultrasonication time on the TiO2 particle size was investigated using AF4-DLS.

Sunscreen (Extraction and AF4-DLS Analysis)

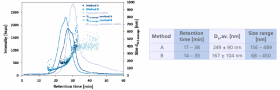

Figure 2: AF4-DLS-fractograms of a sunscreen sample after extraction (Method A: dark blue line and dots; Method B: medium blue line and dots; pure sunscreen matrix: light blue line and dots).

Commercial sunscreens consist of many different ingredients such as organic substances, stabilizers, thickeners, modifiers and inorganic materials. The final formulation can be divided into a basic matrix and the inorganic, nano-sized additives such as e.g. TiO2 or ZnO. Since most of the sunscreens come as oil-in-water (o/w) emulsions (vice versa) the organic components have to beseparated from the nanoparticles. Basically, two methods are envisaged [1,2].

A. Two phase aqueous extraction: These steps include addition of water, ultrasonication, filtration of large material, addition of hexane to the aqueous extract, mixing and extraction. The last two steps (addition of hexane, mixing and extraction) were performed three times. The aqueous layer is finally analyzed.

B. Organic extraction & resuspension: Method B includes addition of hexane, ultrasonification, centrifugation, decanting of the organic layer, resuspending of the residue with water. The addition of hexane and centrifugal steps were repeated three times followed by filtration of large material and analysis of the final aqueous resuspension.

The resulting AF4-DLS fractograms show that, depending on the extraction method, deviating particle sizes and distributions are obtained. Having a closer look into sample preparation, several injections revealed method B (Figure 2, medium blue) to be the superior extraction procedure. Aqueous-organic phase separation (method A, dark blue) proved to be challenging regardless of the number of repetitions and a small layer of incomplete, unseparated phase at the interface was generally observed.

The analysis of the pure sunscreen matrix also revealed additional particulate content, probably microcrystalline cellulose being present as well (Figure 2, light blue; Dh, average = 360 ± 141 nm, Dh, max = 603 nm).

Conclusion

AF4-DLS proved to be a suitable technology for analyzing nanoparticles in complex matrices. Reliable results were obtained by automatic injection taking advantage of the “shaking option” of the AF2000 Autosampler. The standard automated injection technology was not able to inject a representative volume of the sample due to sedimentation of particles. Therefore, the novel “shaking option” enables the user to even analyze complex samples (metastable dispersions, partly sedimenting suspensions) on an automated basis without the need for manual injections. Additionally, two extraction methods for sunscreen formulations were investigated and the results discussed in terms of reliability.

Reference

[1] Contado C. and Pagnoni A., Analytical Chemistry, 2008, 80(10), 7594-7608.

[2] Nischwitz V. and Goenaga-Infante H., Journal of Analytical and Atomic Spectrometry, 2012, 27, 1084-1092.